Coffee Roaster CMS-12 | 12kg Gas Roaster - Manual

Description:

Precision Roasting Technology

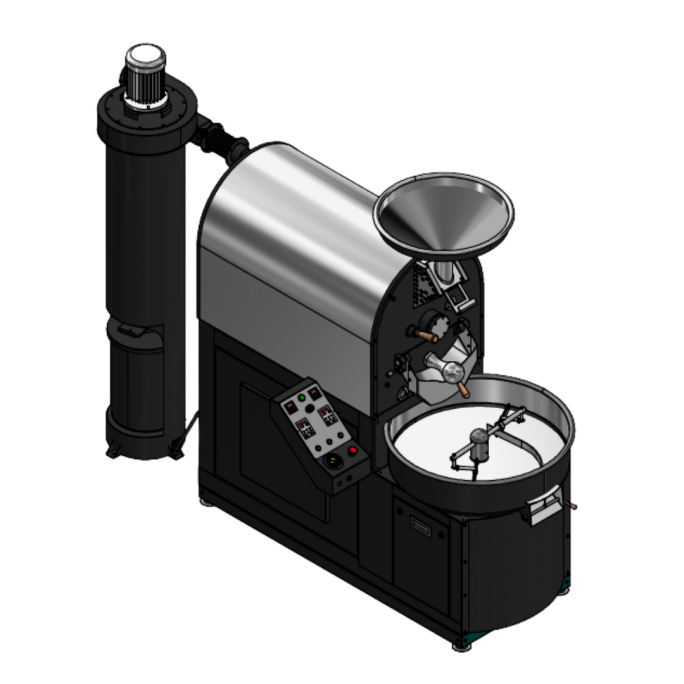

The CMS-12 Coffee Roaster is engineered for specialty roasteries that demand absolute control over their roast curves. Featuring a fully modulated premix burner and a heavy-duty cast iron front lid, this machine offers exceptional thermal stability. With 4 independent motors, it allows for simultaneous roasting and cooling, maximizing your hourly output up to 50 kg.

Advanced Configuration Options

Why the CMS-12 Stands Out

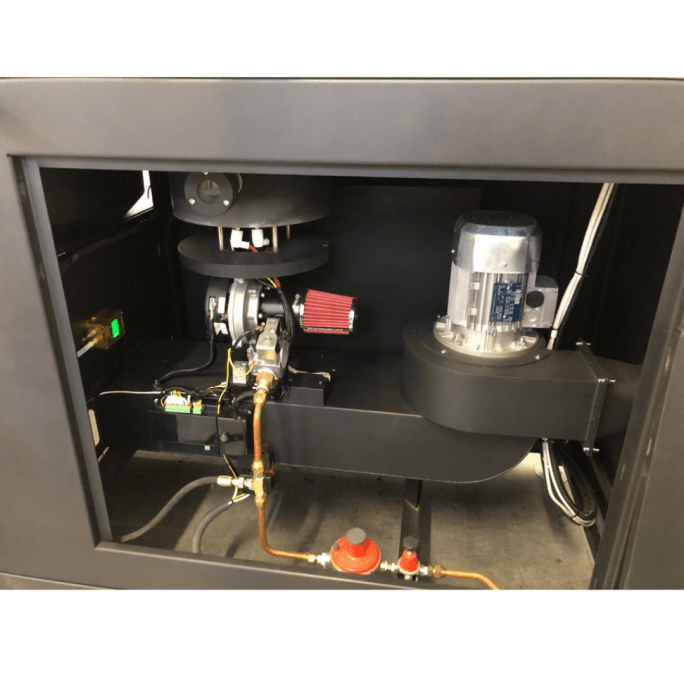

- Clean Combustion: Modulated premix burner with ultra-low NOx emissions for sustainable roasting.

- Double-Wall Engineering: Low carbon steel combined with cast iron for optimal thermal inertia.

- Electronic Precision: Direct control of airflow, drum speed, and underpressure measurement from the panel.

- Safety First: Built to CE standards with emergency stop systems and dual thermocouples (BT & ET).

- Smart Maintenance: External cyclone with easy-empty system and quick-access service points.

Technical Specifications

| Hourly Output | ~50 kg / hour |

| Roasting / Cooling Time | 8–14 min / 2–3 min |

| Burner Capacity | 40 kW (Modulating) |

| Fuel Type | Propane / LPG / Natural Gas |

| Power Requirement | 2.4 kW | 230 V, 50 Hz |

| Origin | Vietnam |

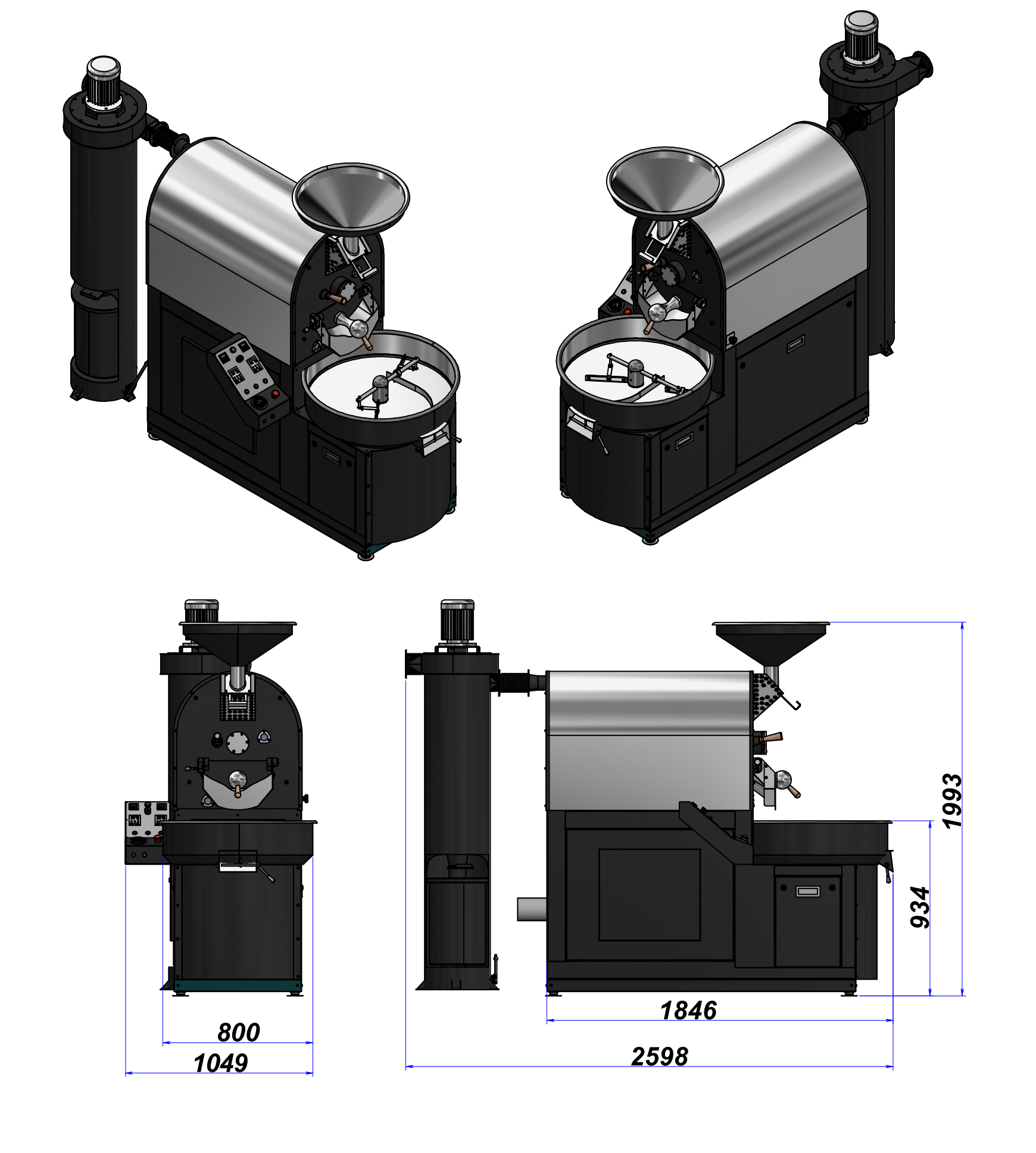

Dimensions & Layout

Detailed dimensional drawing for roastery planning:

Frequently Asked Questions

Does the CMS-12 support automated roasting?

Yes. While the standard version is Artisan/Cropster ready for logging, the Automation Package (+€4000) allows the software to take full control of the burner, airflow, and drum for 100% repeatable recipe-based roasting.

Why use 4 independent motors?

Independent motors allow the cooling fan and stirrer to run while you are roasting the next batch. This parallel workflow significantly increases your daily production capacity.

What gas pressure is required?

The roaster operates efficiently at a gas pressure of 20–40 mbar. It can be configured for Natural Gas or LPG upon order.