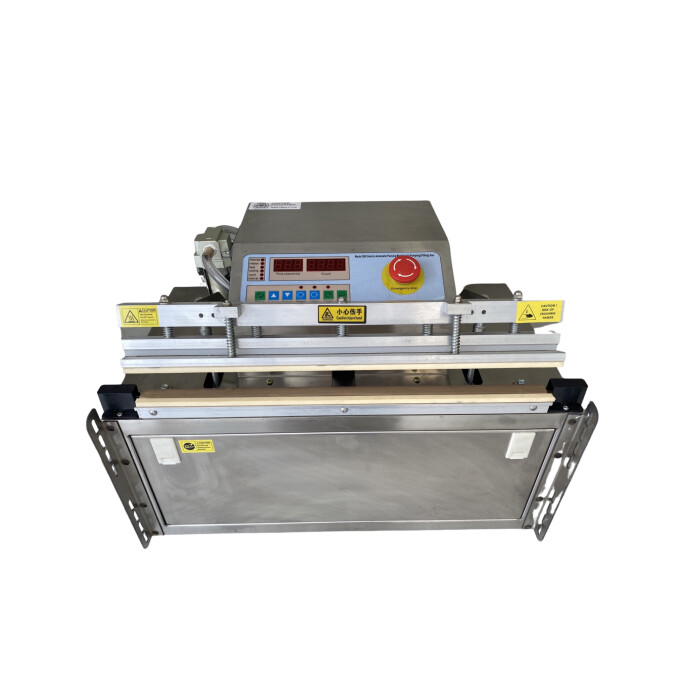

Vacuum / Nitrogen Injection Heat Sealer VF-500

Description:

Preserve Freshness with Precision

The VF-500 Vacuum Sealer is an efficient and economical solution for roasteries committed to preserving the aromatic integrity of their beans. By utilizing nitrogen injection and high-power vacuum cycles, this machine eliminates oxygen — the primary enemy of coffee freshness. Designed for production efficiency, it features a stainless steel nozzle and a robust, quiet-running high-flow vacuum pump.

Industrial Grade Engineering

- Advanced Gas Flush: Flush your bags with nitrogen to maintain the "just-roasted" profile for months, even in whole bean coffee.

- Integrated Filtration: Specifically designed for coffee environments; the filtration system automatically clears debris and dust from the vacuum lines after every cycle.

- Airtight Security: Bottom-heated 8mm wide sealing elements ensure a reliable, industrial-strength closure on foil-valved gusseted or flat laminated barrier bags.

- Ergonomic Workspace: Includes a fully adjustable stainless steel workshelf to accommodate different bag heights and streamline your packaging flow.

| Model | VF-500 Nozzle Vacuum Sealer |

| Sealing Width | 8 mm |

| System Modes | Vacuum / Gas Flush / Seal |

| Pump Type | High-Flow Industrial Vacuum Pump |

| Compatible Bags | Foil, Mylar, Laminated Barrier (Flat/Valved) |

Application Compatibility

The VF-500 is specifically optimized for flat bags and valved barrier pouches. It is not recommended for sealing traditional side-gusset bags due to the specific nozzle-seal geometry required for those bag types.

Frequently Asked Questions

Why should I use Nitrogen Injection?

Nitrogen is an inert gas that replaces oxygen inside the bag. Oxygen is responsible for the oxidation of coffee oils, which leads to staleness. Gas flushing with the VF-500 can extend the shelf life of your coffee significantly while maintaining its delicate volatile aromas.

How does the dust filtration system work?

Roasting environments are naturally dusty. The VF-500 features a dedicated filtration cycle that clears out coffee particles and debris from the vacuum lines after every cycle, preventing clogs and ensuring long-term pump reliability.

The VF-500: Professional freshness management for quality-focused coffee roasters.

Product Reviews Vacuum / Nitrogen Injection Heat Sealer VF-500

5 / 5

Such a great machine for packing indian food!